Heathcote Industrial Plastics have been manufacturing composite leaf springs in the UK since 1979, and are world leaders in the manufacture and supply of composite leaf springs for vibratory conveyors and feeders, offering unparalleled levels of service and support.

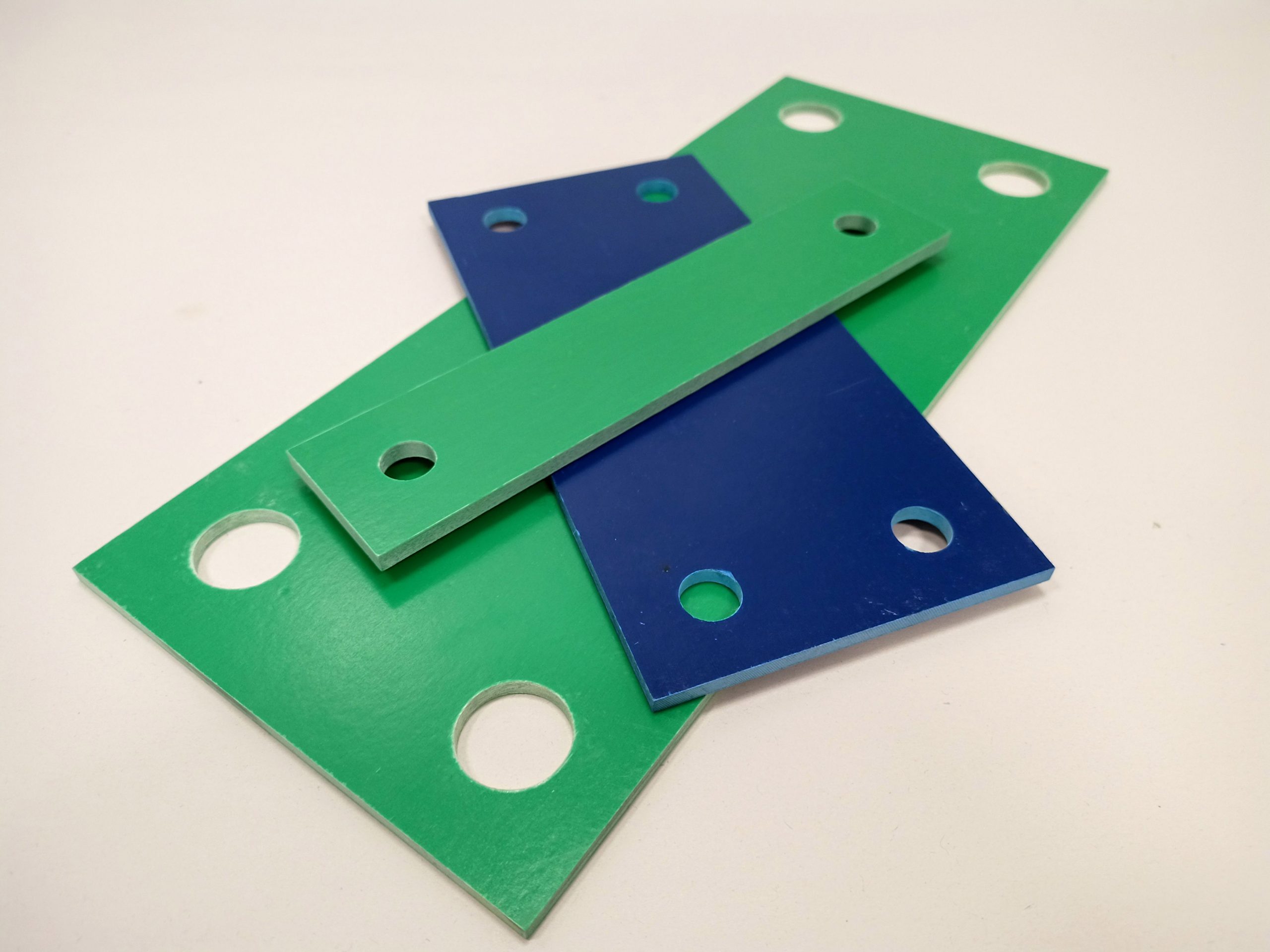

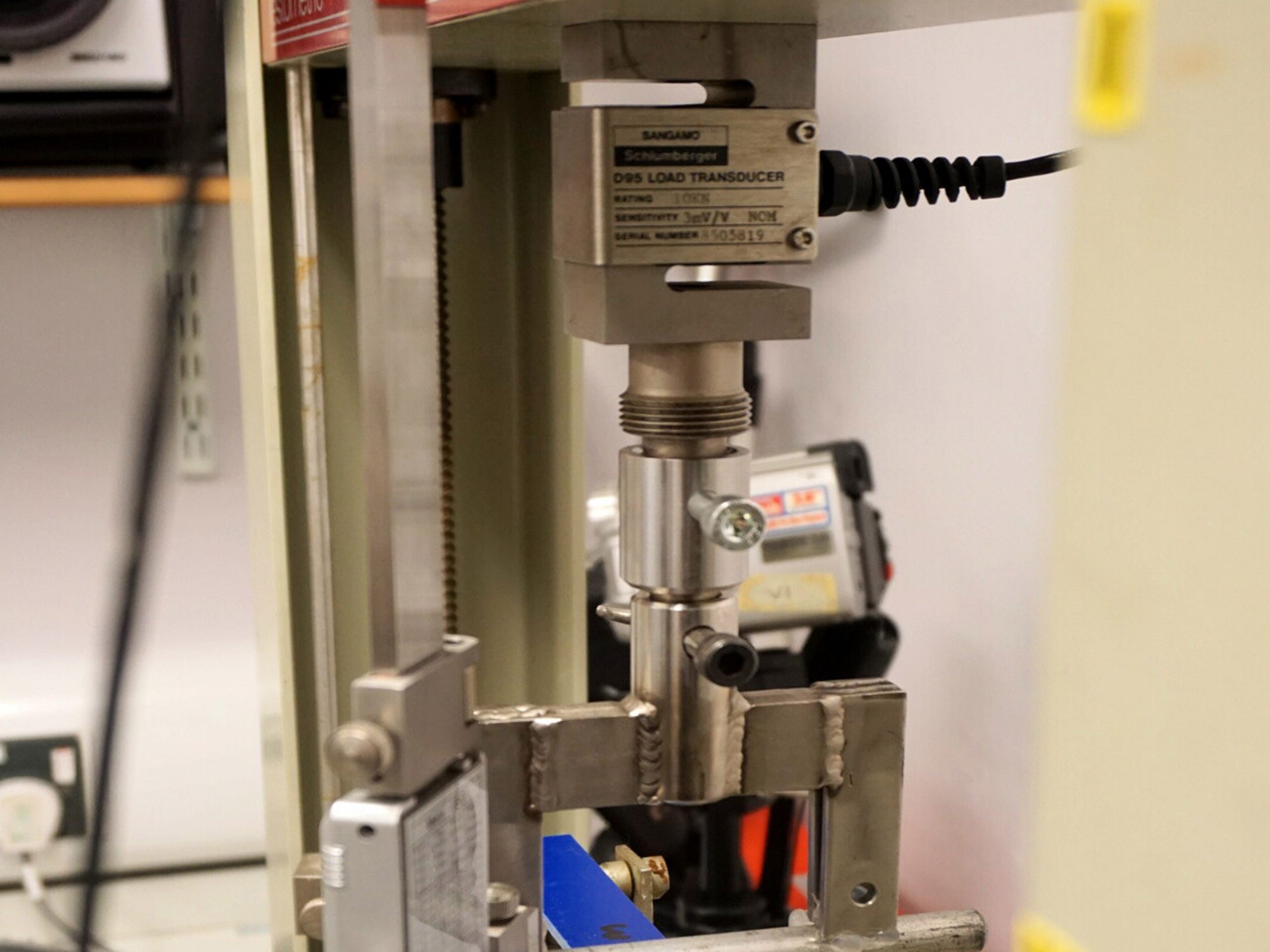

We manufacture all of our own composite materials in our factory here in the heart of Staffordshire. Combining the finest raw materials into our unique composite spring panels, which are engineered for performance and reliability, and all manufactured under our ISO9001 accredited quality system.